- Home

- About Us

- Diploma Programs

- Certificates

- Cannabis

- Healthcare

- Pharmaceutical

- Corporate Training

- CannSell Expert Certification

- Information Technology

- ESL Program

- Psychedelics

- Food Handler Certification

- Apply

- Student Services

- Events

- Blogs

- R&D

Cannabinoids are compounds found in the cannabis plant that have a variety of potential therapeutic applications, including pain relief, anti-inflammatory effects, and treatment of neurological disorders. However, cultivating cannabis plants can be costly and time-consuming, which has led to interest in producing cannabinoids using other methods, including yeast production.

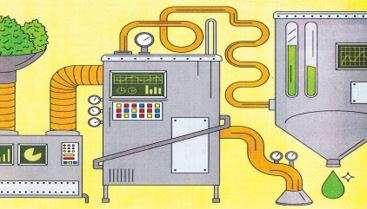

Yeast production of cannabinoids involves genetically modifying yeast to produce cannabinoids instead of alcohol or other compounds. The process involves introducing genes encoding for cannabinoid biosynthesis enzymes into the yeast genome, allowing the yeast to produce cannabinoids through a series of biochemical reactions.

Several companies, such as Librede and Demetrix, are currently working on developing yeast-based production methods for cannabinoids. These methods offer several advantages over traditional cannabis cultivation, including faster production times, lower costs, and more consistent product quality.

One study published in Nature in 2019 demonstrated the successful production of THC and CBD using genetically modified yeast. The researchers used a combination of genetic engineering and chemical synthesis to produce the cannabinoids in large quantities. They also demonstrated that the yeast-produced cannabinoids had similar chemical and pharmacological properties to those produced by the cannabis plant.

Overall, yeast production of cannabinoids is a promising area of research that could offer a more sustainable and efficient way to produce these compounds. However, further research is needed to optimize production methods and ensure product quality and safety

Cannabis yeast is a genetically modified yeast that has been engineered to produce cannabinoids, such as THC and CBD, through a fermentation process. Here are the steps involved in the production process:

It’s important to note that the production of cannabis yeast is a relatively new technology and is still being developed and optimized by researchers and companies. Additionally, the use of genetically modified organisms (GMOs) in food and medicine production is a controversial topic, and the safety and regulatory approval of these products may vary by country.

For more information on cannabis biotechnology and cannabis tissue culture:

https://www.nacptpharmacollege.com/course/cannabis-tissue-culture-and-bio-technology-formulation/

Medical Office Administration

Medical Office Administration